Table of Contents

warehouse management

Description

With warehouse management, you now have a simple way of managing incoming and outgoing materials. The material stock is managed for the material article data. Incoming and outgoing stock material can be checked by entering the delivery note in the Post calculation be posted or within the split postings of supplier invoices in invoice can be managed as incoming materials.

Activate warehouse management

Select the entry in the application menu Activate warehouse management.

Im Address manager becomes a new supplier address Warehouse- [own company name] created as well as in the Project management the internal construction site Warehouse (LV number: Lager-01-0001) for the new address.

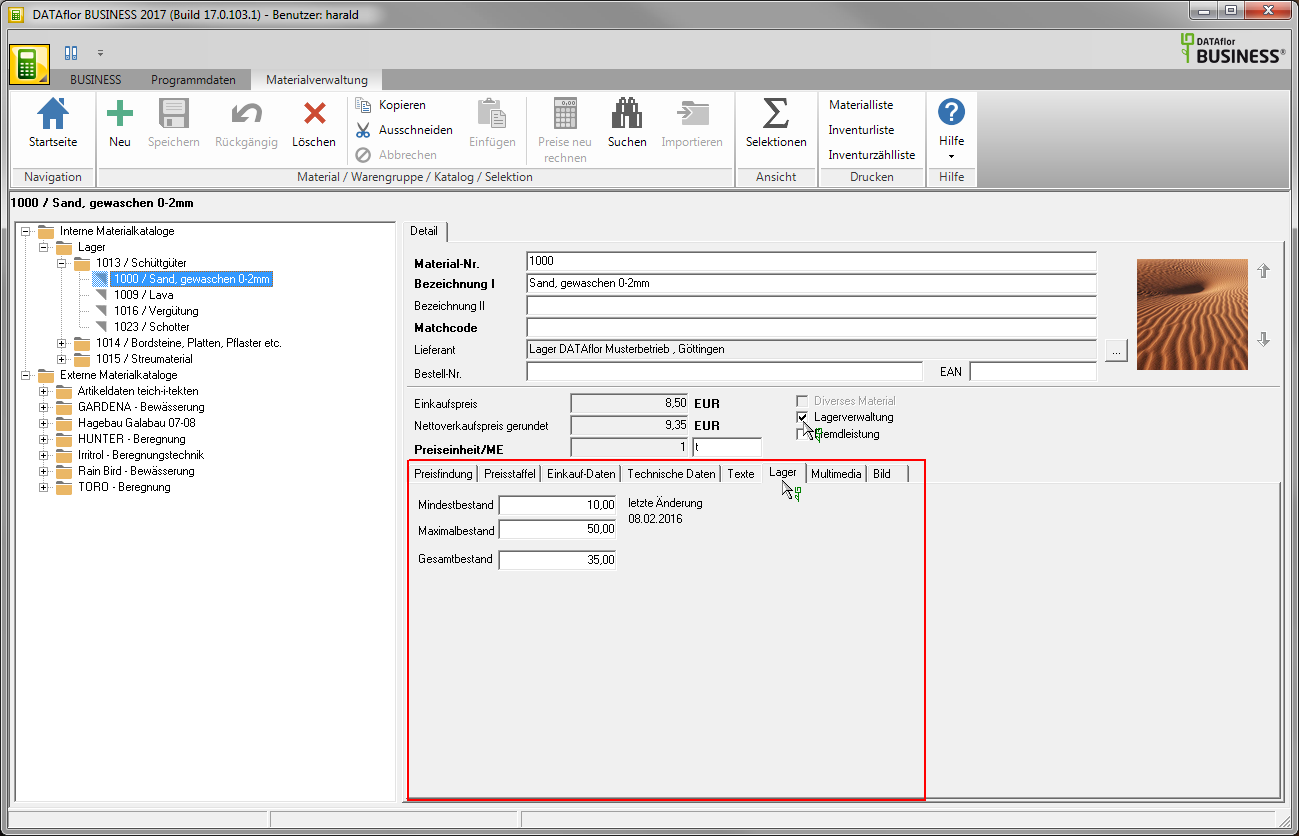

Within the material management, the option must be set for the materials for which incoming and outgoing goods are to be taken into account warehouse management activated and the minimum, maximum and total stock (= actual stock) entered.

Post warehouse receipts

A warehouse receipt can be in BUSINESS can be captured in two ways:

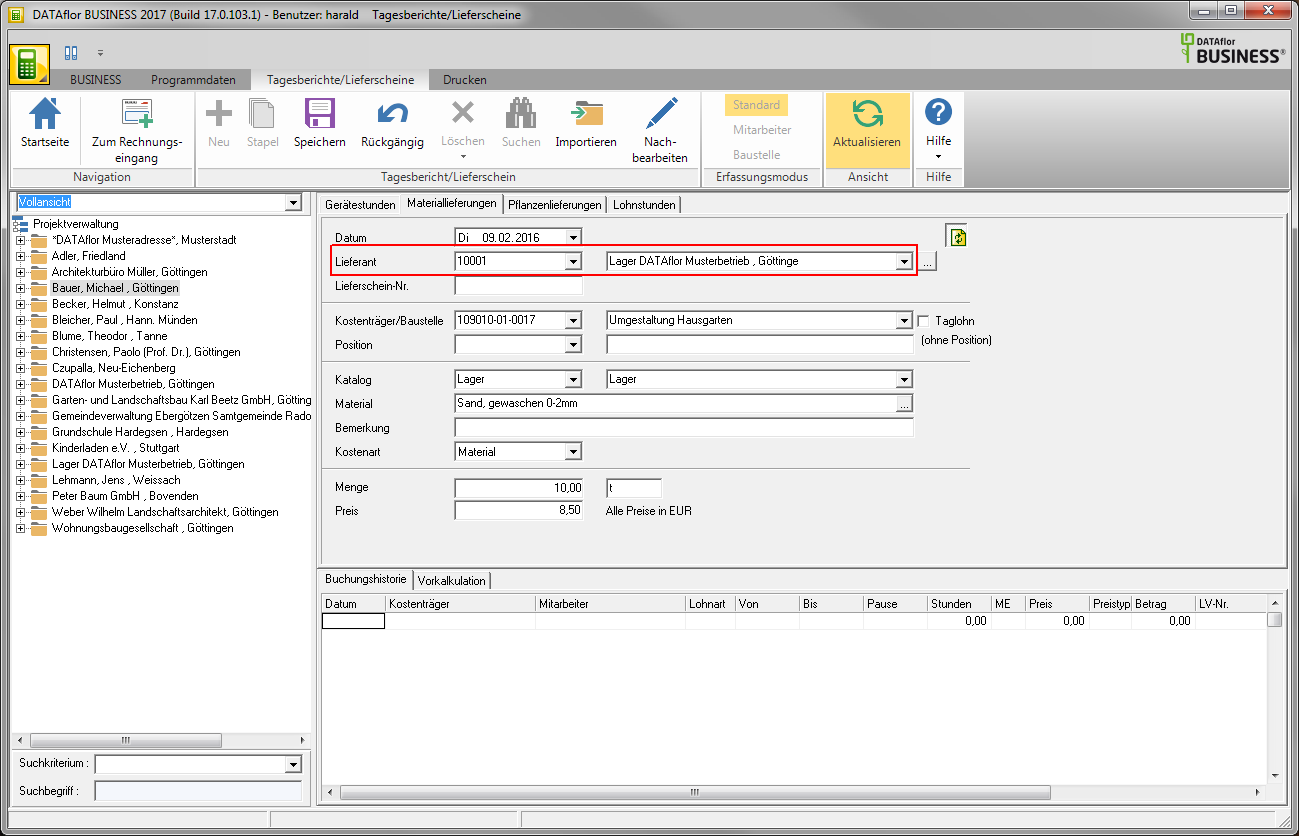

- 1. by entering a material delivery note in the Post calculation at the construction Warehouse

- 2. by entering a material allocation posting of a supplier invoice in invoice at the construction Warehouse

If the limit values of the minimum stock or the maximum stock are exceeded or if the total stock is negative, a warning is issued. However, posting is still possible, as is the cancellation of the process. For example, it can happen that the total inventory becomes negative in the meantime, because a warehouse issue posting is made before the corresponding warehouse receipt posting (e.g. due to unsorted delivery notes or posting sequence). If necessary, regulate this through your company organization (e.g. always book entries first, then withdrawals).

You will receive a warning if the unit of the posting record does not match the unit of the material master data record (occurs, for example, when the pre-assigned material master data unit is changed manually from m³ to to). If you still want to post such a data record, you have to enter the amount converted accordingly so that there are no conversion errors.

Post inventory issues

To post material issues from the warehouse, enter in the Post calculation a material delivery note for the supplier Warehouse- [own company] to any construction site.

If the stored minimum stock is not reached, a negative stock or a unit difference is displayed, a warning is displayed.

Evaluation of warehouse postings

Within all construction site and time-related Evaluations of the final costing are the bookings on the construction site Warehouse-01-0001 shown in brackets and are not included in the totals.

The cost burden of construction sites through the delivery of material from the warehouse is guaranteed by the bookings of the storage material on the specific construction site (by supplier {warehouse-own company}).

The delivery note overview is an exception. Here are the costs for the warehouse access to the construction site Warehouse-01-0001 calculated (= amounts of incoming material deliveries from various suppliers). The deliveries of the supplier Warehouse- [own company] are shown in brackets and are not included in the total.